Spodumene

For the OPTIMUM sorting of spodumene, we would like present the VENTUS.

BENEFITS

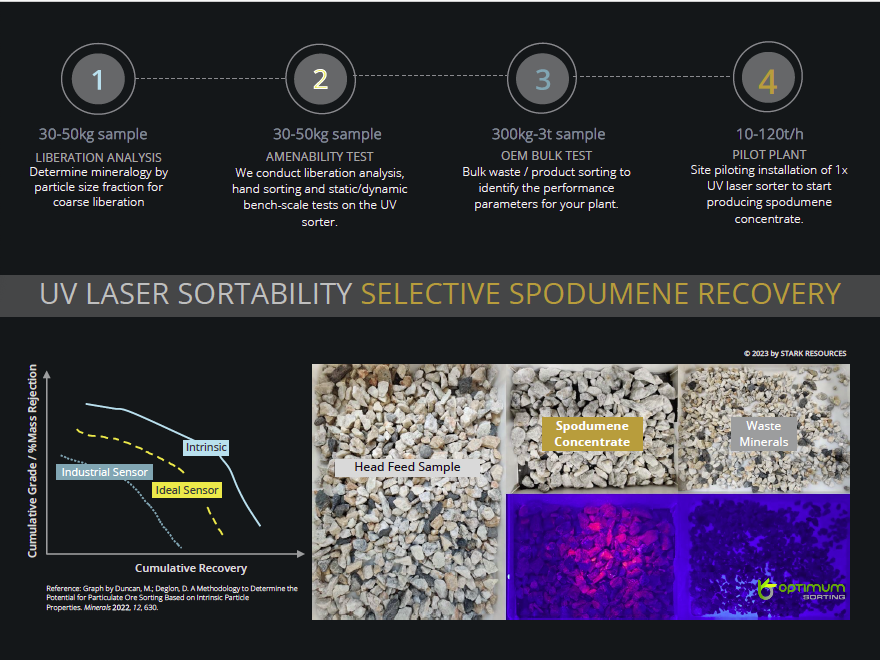

UV laser sorting is truly unique in that it can SELECTIVELY recover spodumene from host pegmatites, exploiting the unique properties of the target mineral, i.e., the unique UV fluorescence of spodumene crystal lattice impurities. No other sorting currently available on the market can achieve this. Often other technologies sort on a "proxy mineral" to recover Lithium minerals, but what if that proxy mineral isn't evenly spread throughout the resource?

The economic implications of this technology for the Lithium industry is groundbreaking! By feeding a coarsely liberated 1.5%Li2O RoM , it is possible to produce a high-grade spodumene concentrate (>SC3), DRY!

UV sorting could be used as preconcentration step ahead of DMS, for example....a "Rougher-Cleaner" type flowsheet.

FEATURES

The uniquely patented UV laser technology allows for direct spodumene detection. In combination with an AI driven interface, settings can be tweaked in such a way that you can sort on spodumene content percentage of each sample that passes through the sorter, directly resulting in the required results at the end of the line, whether you’re purely looking for a waste sort, a low + high grade sort or purely high grade sort.

TYPICAL DEFECTS

Unmatched recognition/discrimination of spodumene (whether whie, light green, dark green, translucent,…) from waste ore such as:

- Quartz

- Basalt

- And many more