Sorting cherries

BENEFITS

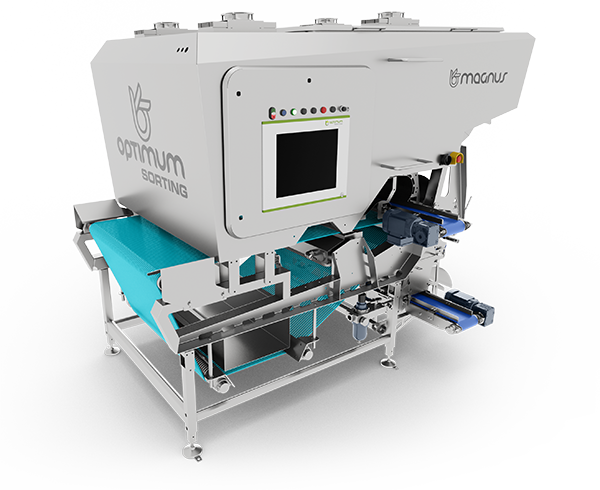

Sorted fresh on MAGNUS:

- Gentle handling

- Small footprint

Sorted IQF or fresh on VENTUS:

- High capacity

- Double-sided laser inspection

TYPICAL DEFECTS

- Discolorations

- FM

- Pits

- Wind whip

- Doubles

- Rotten

- Stems

- Leaves

Sorted fresh on MAGNUS:

Sorted IQF or fresh on VENTUS:

With its advanced high-resolution color camera system, the MAGNUS accurately detects deviations in color, size, and shape.

To further improve sorting accuracy, the MAGNUS can be equipped with our latest laser technology. By combining multiple lasers with specific wavelengths, the MAGNUS easily identifies structure and biological characteristics, ideal for detecting soft and shriveled fruits and removing foreign materials such as wood, plastic, stone, and glass.

The MAGNUS boasts an unmatched laser scanning speed of up to 4000 scans per second, achieving an optical resolution of 0.3 mm. This enables it to accurately detect stems.

The MAGNUS offers both a single and dual rejection system to separate color defects from soft or rotten fruits and foreign objects. In dual rejection or ThreeWay mode, the MAGNUS ejects soft or rotten fruits downwards, ensuring that their ejection path is separate from that of good product to prevent contamination by juice.

The VENTUS may be equipped with up to 16 lasers (and 32 laser detectors). With an impressive laser scanning speed of more than 4000 scans per second, it offers the highest resolution of all laser sorters on the market. In addition, all different laser signals are processed simultaneously by our Multi Dimensional Laser System (MDL) system, which outperforms all other systems.

In order to get an excellent good-to-bad ratio even for the smallest products, you can equip it with a high-resolution valve system: ultra-fast and small blowing jets with a center-to-center distance of 4.6 mm.